Resonance Analysis: Tips and Techniques for Cable Line Optimization

In the present industrial stage, the inspection and

performance of wire systems, particularly those which are used as cables for

the control and instrumentation applications is critical for the safety and

proper functioning. The challenge of aging of wire systems is growing across

oil & gas, transportation, and some defense sectors. The nuclear industry

is an example of the extended lifetime that cables are required to uphold,

which is often offered above 40 years. Nevertheless, the challenges of harsh

environmental circumstances and correcting by-pass impedance are still to be

addressed leading to the development of the more sophisticated techniques such

as Cable Line Impedance Resonance Analysis (CLIRA).

Understanding

CLIRA: A Comprehensive Measure Proposal

Cable Line Impedance Resonance Analysis (CLIRA), also

linguistically the same with Line Resonance Analysis (LIRA), is now being used

as a method to monitor cable status. The CLIRA (a short- for “Cable Linear

Interaction and Response Analysis”) tool employs

transmission line theory to carry out a cable behaviour

study under diverse conditions. First, CLIRA examines the complex cable

impedance spectrum, allowing to recognize such insulation imperfections like

thermal degradation and mechanical damage.

Key

Principles of CLIRA:

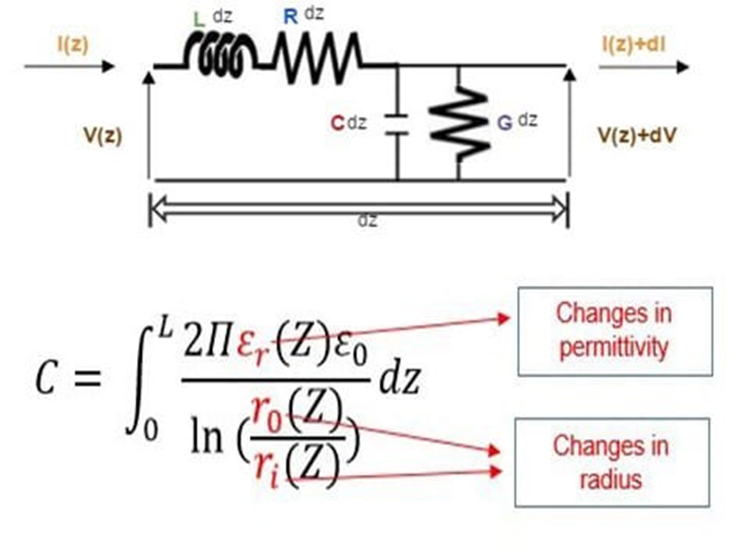

Transmission Line

Theory: The transmission line theory from the CLIRA places emphasis on how

the action of the cable depends on the sizes of the signal's wavelength and the

cable's length.

Characterization

Parameters: In its performance CLIRA uses the skin effect resistance (R),

the sheathing inductance (L), the cable capacitance (C) and insulation

conductivity (G) as the parameters to evaluate the cable behaviour.

Impedance Spectrum

Estimation: CLIRA software utilizes the institution of their own algorithms

which determine the comprehensive layout of the cables and then estimates both

local and global degradation.

Tips for

Effective Cable Line Optimization:

Baseline

Measurements: First of all, you have to define your initial scope of the

measurements, for it will allow to understand the state of the system after the

tests and analysis.

Damage Detection:

Engage the use of CLIRA together with other techniques, including TDR, for

reliably detecting the impact. Despite the fact that TDR is an extremely

accurate method to determine the exact wiring defects, CLIRA provides a picture

of a cable’s overall health.

Custom Algorithms:

Features such as custom algorithms within CLIRA for precise parameter

determination like phase velocity, not dependent on cable length or load

attributes made possible.

Continuous

Monitoring: CLIRA should fit in a multiparametric monitoring system and

augment material screening for the continuous evaluation of cable health, with

special attention given to nuclear power plants operating environment.

Ultra-sonic and other Non-Destructive Testing of cables that

are tested without the need of energising the cables with high voltages. More

likely to be used in a ‘high risk’ scenario than other methods

LIRA has been made as small as to be placed on electrical

cables up to few hundred kilometres long and is gradually evolving as a

condition monitoring or fault locating tool in the distances (like, for

instance, a submarine cable that connects an off-shore platform to the grid).

Through IRLA, it is possible to test for and to find the

various types of flaws and faults in insulation such as temperature and

radiation damage, moisture intrusion fluid as well as mechanical impact being a

fair sample.

LIRA makes use insulation conditions to impose a

relationship between which and capacitance and therefore calculates the

impedance spectrum (amplitude and phase) as the applied signal increases over

the wide frequency band.

The capacitance of a cable changes as a function of changes

in the cables permittivity and changes in the cable’s radius, as shown

below:The capacitance of a cable changes as a function of changes in the cables

permittivity and changes in the cable’s radius, as shown below:

R = series resistance

L = series inductance

G = parallel conductance

C = parallel capacitance

The changes in the permittivity and radius determined

the neighboring impedance. Impedance mismatches show up exactly where

immunancies are the most - specifically, it is when the cable ends. LIRA will

generate standing wave patterns on short open circuits by comparing them to

existing ones and promptly informing the system operators of slow impedance

value changes.

Features

and Benefits

LIRA can be applied to cables hundreds of kilometers long,

in contrast to VLF associated with the use of the latter being restricted to

the cables with a length of maybe 10km.

Useful for cable testing where hazard of applying energy to

fully working voltage range exists.

With this technology you may apply fingerprinting used as

your initial tool that allows you quickly to distinguish between the good cable

and the bad one. This strategy showed the best outcomes.

Precise evolution of the impedance value will reliably demonstrate

the presence of the anomaly.

Faults are isolated into a section located within 0.3% of

the cable system.

precisely pinpoint sources of joints that are typically

impossible to recognise.

LIRA can detect the following phenomena:

●

Global insulation degradation

●

High Temperature damage

●

Moisture ingress

●

Radiation damage

●

Mechanical effects/defects

*Note: When the highest sensitivity is the goal, expect a

slight loss of signal at the multiple impedence changes so it is recommended to

test from both ends. However, this does not need to be done.

Maximizing

Sensitivity and Efficiency:

In order to achieve most sensitivity and be able to test

signal gain at each location of impedance changes, it is highly recommended to

conduct LIRA testing from both ends of the cable. However, it is not a formal

requirement yet which gives priority to achievement of detection accuracy and

efficiency, particularly, in sophisticated cable networks.

Conclusion:

We conclude that the Best

Cable Line Impedance Resonance Analysis technique, is a very safe,

reliable, and highly effective method for diagnosing line deterioration and may

be performing necessary maintenance during the process of a line performance

enhancement. It is the most advanced non-destructive technology known for

comprehensive fault detection, accurate localization and being environmentally

non-invasive that is the best solution for ensuring safety and reliability in

modern industrial technology.

Comments

Post a Comment